Standards: GB, GB/T, IEC, etc.

Scope of application: It is applicable to multi-channel high-temperature on load aging test of high-power modules such as new energy vehicle controllers, inverters, DCDC.OBC.

2. Main characteristics and technical indicators

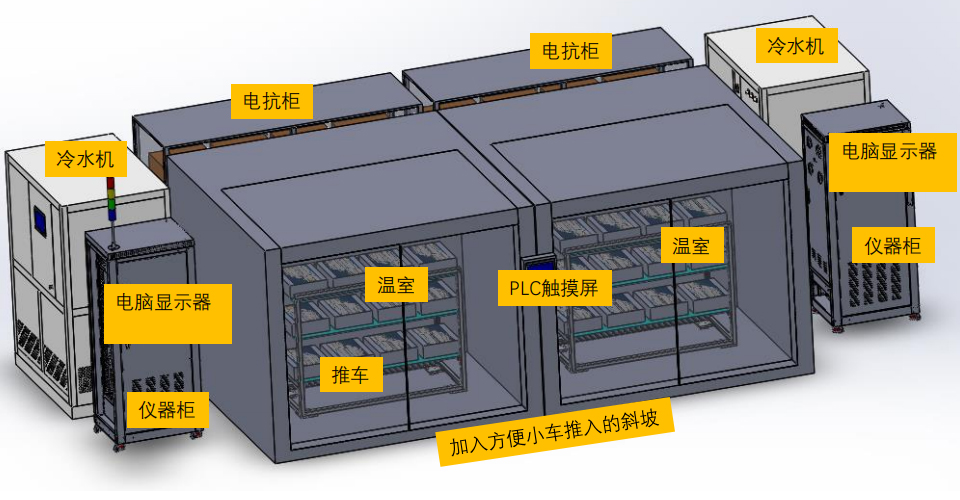

·The temperature box, water cooling box, load cabinet (reactance and electronic load are optional) and electric control cabinet are placed separately to facilitate expansion and maintenance and meet the requirements of high-power anti-interference.

·The test conditions can be directly called out from the aging test database, with flexible configuration and convenient operation

·The working current and test voltage of electronic load can be programmed. Load current can reach 800A

·The electronic load is bidirectional, with power grid feedback and energy saving.

·The electronic load can be connected in parallel to expand the output capacity.

·One instrument cabinet controls one temperature box to provide 12 aging channels at the same time. Communication, power supply and load. Each acquisition channel is completely independent. Each aging channel test scheme can be configured arbitrarily. Including, voltage, current calibration, calibration. Temperature test, rotary transformer, CAN communication, LIN communication, etc

Product name | High temperature aging test system of the whole machine | ||||

Test system | The whole test system includes 1 control cabinet+2 load cabinets+1 temperature box+1 water tank | ||||

Test channel | 12 | ||||

Test capacity | 0-12 optional. Each channel can run different processes. Allow mixed testing of different products | ||||

Power Supply | 6 sets of 15KW voltage output can reach 1000V | ||||

load | ◆Six three-phase AC electronic loads for each load cabinet | ◆ Each load cabinet provides 6 groups of three-phase loads with 18 reactances | |||

| ◆ Each circuit of electronic load has independent overrun protection function; | ||||

Heat dissipation capacity | The maximum heat dissipation power of each water tank is 5KW, | ||||

water tank | Temperature change rate: 5℃/min ±0.1℃ | Coolant flow rate: 0~20L/min ± 0.5 single station adjustable | Water pressure:≤2.5Bar | ||

Hotbox | Temperature change rate:5℃/min | Temperature unbalance:≤±2℃

| Temperature range of ambient chamber: room temperature - 85 ℃ | ||

Upper computer | Industrial computer host, LCD, special keyboard and mouse. | ||||

basic function | ◆ Test current setting; Upper limit setting of test current, voltage and shell temperature parameters; Aging time setting; ◆ Real time monitoring and display aging parameters (I, V, Tc), aging time and aging progress; ◆ Real time record and save aging parameters (I, V, Tc); ◆ Judge whether the limit is exceeded in real time, give an alarm and record the overrun station and the overrun time, and turn off the electronic load of the overrun station in time; ◆ The aging parameters can be easily called, test reports can be generated, and relevant change curves can be drawn. ◆ Voltage and current calibration. Temperature test, rotary transformer, CAN communication, LIN communication, etc | ||||

Grid Requirements | 3-phase AC380V, 196kW | ||||

Overall dimensions | WхHхD:(cm) | ||||

weight | About 2000kg | ||||